The Last Job of the Day: Caring for Your Truckmounted Equipment, Hose, and Cleaning Tools

If you have ever worked in a restaurant, you know the last chore of the night is always cleaning up the kitchen. That’s because it’s important for the kitchen to be fresh, clean, and of course healthy at the start of each new day.

The same can be said when it comes to caring for truckmounts. While many carpet cleaning technicians and cleaning professionals may believe their day should be “over and out” when they finish cleaning the carpets, it’s actually smart to make cleaning and caring for the machine itself the last job of the day. Always remember that customers will surely notice the machine you use. What kind of impression will it give them if your truckmount is soiled and dirty?

Before adding this step to your daily routine, however, be sure to review the manufacturer’s instructions as to how to care for your truckmount. Some machines may require specific maintenance on a set or regular schedule.

For most truckmounts, the following maintenance steps should be taken at the end of the work day:

- Check fluid levels – it is always a great idea to do a quick check of your engine oil, blower oil, and solution pump oil. Many vacuum blowers are equipped with “sight” tubes to make part of this job easier. Always follow the recommendations of your machine’s manual.

- Lubricate your vacuum blower with a quick squirt of lubricating oil. HydraMaster recommends TKX by LPS lubricating oil for the vacuum blowers used on its truckmounts. About a 5 second squirt works ideally. Many HydraMaster Truckmounts are quipped with a lubricating port on the front of the machine to assist with this.

- When cleaning your truckmount at the end of the day, be sure the tank is clean and fresh by flushing it with pure water. Leave the tank empty and prop the lid open to allow it to air dry. It is always a good idea to rinse out and clean your vacuum recovery tank, your vacuum tank drain, filter, and lint basket. It your machine is equipped with an automatic pump-out system for wastewater, don’t forget to clean and rinse it out too.

- You may also find it necessary to occasionally run a little deodorizer (CleanMaster OdorMate Tropical Breeze works great!) through the vacuum hoses along with some CleanMaster DeFoam. Be sure and rinse thoroughly. This keeps the hoses clean and sanitary and helps make sure air can move freely through the hose.

- You should also de-scale the unit occasionally. We recommend the safer to use CleanMaster TM DeScaler throughout the system. Make sure you follow the specific instructions from your machine manual to properly descale your machine. Also rinse the chemical jug to clean out any residue and flush the chemical system with white vinegar to neutralize the system and clean out any residue. Again, check the owner’s manual for information about if and how you should perform this task on your particular machine.

- Rinse the machine’s wands and make sure they and all brushes are lint and hair free. It is easiest to clean these while they are still wet. Use a wire comb to pull lint, hair, and other debris from brushes. Also, make sure there is no fraying or cracks on the hoses, wiring and cords on rotary extractors. These invariably become worse over time.

- A soft toothbrush may be used to clean the jets on the wand to remove mineral deposits.

- Wipe the machine down from top to bottom, and don’t forget the wheels on rotary extractors. This will ensure that you don’t roll any soil from yesterday’s job into the first job tomorrow morning.

- The end of the day is also a good time to inspect and listen to the machine. Investigate anything unusual, including any unusual sounds you might hear when the machine is operating. If something sounds different than normal, check it out. We have found that sound changes or unusual noises are very often the most effective way for a “not mechanically inclined” cleaning technician to save the day when it comes to maintenance. “If you hear something, say something!”

- Finally, it’s a good idea to check your chemicals at the end of the day as well. Make sure they are secured and the tops are tight, and wipe the containers down. This is also a great time to replenish your chemical inventory for tomorrow’s jobs.

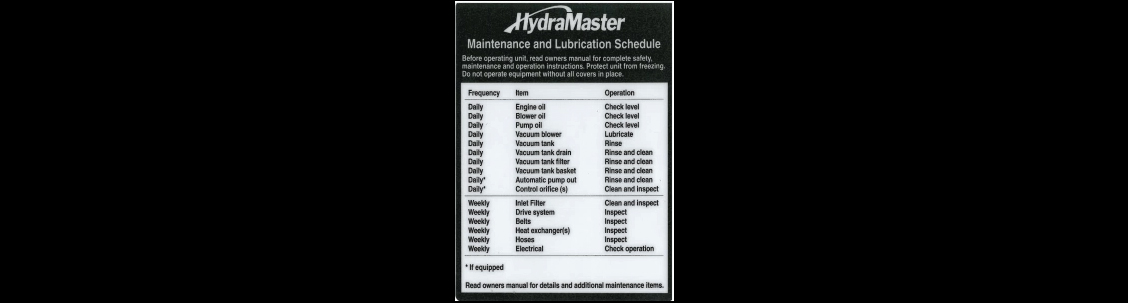

HydraMaster Truckmounts include maintenance and lubricating schedule decal that is mounted right onto the visible area of the waste tank to help you remember many of these steps. But it is also a good idea to include this list on a checklist that the technicians who brought the truck back to the shop are required to sign off on. Remember the old Fram oil filter commercial – “You can pay now, or you can pay big time later.”

Remember, keeping your equipment and chemicals clean and well maintained ensures worker safety, enhances professionalism, and ultimately makes your next job a lot easier, faster, and more productive.

Tags: care, cleaning, descaling, easier, fluids, lubrication, maintenance, productivity, professionalism, truckmount, truckmounts