- Condition and Wear: Used truckmounts may have wear and tear from previous usage, and they might not perform as efficiently as a new machine. Parts may be worn, and the overall condition may affect its effectiveness and longevity.

- Maintenance History: The lack of a complete maintenance history from the previous owner(s) means you cannot say for sure they have followed the recommended intervals for oil and other liquid changes, filter changes, etc.…+ This can be a significant risk for you as the new owner. You cannot see inside the blower, engine, pump, or heat exchanger to see if it has been properly maintained. If the previous owner did not maintain the equipment properly, it could lead to more frequent breakdowns and higher maintenance costs for the new owner.

- Limited Warranty or None: Unlike new equipment that often comes with a manufacturer’s warranty, used equipment may have limited or no warranty coverage. With many truckmount manufacturers and major component manufactures, even if there is a remaining warranty, it may not transfer to you as the new owner. This means that any issues or malfunctions that arise after the purchase may result in additional repair costs for the buyer.

- Obsolete Technology: Older models may lack the latest technological advancements, making them less efficient and effective compared to newer equipment. This can impact on the quality of carpet cleaning and may require more effort and time to achieve the desired results. Many manufacturers only support a truckmount by maintaining a parts inventory for a certain number of years after they discontinue a model. Parts can become harder and harder (and more expensive to find). Some smaller truckmount manufacturers change parts on a regular basis within the same model. Just because they still sell that machine does not always mean it is built with the same framework and components now.

- Hidden Defects: There may be hidden defects or issues not immediately apparent during a visual inspection. These could become apparent only after the equipment is put into operation, leading to unexpected repair costs.

- Compatibility Issues: Used equipment may not be compatible with newer accessories or technologies. This can limit your ability to upgrade or integrate the equipment with other tools and systems.

- Resale Value: As equipment ages, its resale value decreases. This may impact your ability to recover the initial investment when you decide to sell or upgrade the equipment in the future.

- Regulatory Compliance: Older equipment may not meet current safety and environmental standards. This could pose regulatory compliance issues which could potentially shut you down.

- Who is giving you advice: Often, before you buy a truckmount based upon an album of pictures on a social media site, professional cleaners will go on-line and ask for other’s opinions about that particular brand and model of truckmount. Even when the feedback is positive, keep in mind those responders do not know any more than you do about how well the machine has been taken care of.

To mitigate these risks, it is crucial to thoroughly inspect the used equipment, request maintenance records, and, if possible, test its performance before making a purchase. We always recommend you take the machine you are considering buying into your local HydraMaster Distributor and let their service team give it the once over before you buy it. If the seller will not let you do that. Our recommendation is to consider buying used equipment from reputable distributors who provide transparency about the equipment’s history and offer some form of guarantee or back-up. The HydraMaster CDS Direct Drive Truckmount consistently provides the highest resale value of any truckmount built in the industry. The proven track record of this machine is unparalleled. Still, you need to look at the condition of the van AND machine when considering buying a used CDS.

What drives a person to buy used equipment? Quite often, it is budget. As a start-up or newer business, they simply do not have the capital to buy or credit history to borrow the money for a new machine. So, they scrape together whatever they can and buy what matches that price point. Not a great long-term plan for quick success in their new business. Another mistake they often make is thinking they must have a bigger, “badder” machine than their budget or credit history allows. So, they buy an older bigger truckmount for the price they could get a brand new smaller truckmount. Think about this, there are thousands of carpet cleaning companies successfully operating with portable extractors only, or Very Low Moisture Equipment only. You do not have to have the biggest, “baddest” truckmount to build your business and wow your customers with the cleaning performance of a TITAN 325.

Our advice, lean on the expertise of your local distributor to guide you through the process. Many finance companies have special start-up packages available for someone just like you. At least fill out an application. The worst thing that could happen is you cannot get the financing and you are back to square one. Feel free to go ahead and check it out with the people who say they are your “buddies” online in a social media forum or group. But understand, many of them have an agenda for giving out advice on-line that has nothing to do with contributing to your success. Carefully sift through the “advice” and “experience” you are provided. Some of it is no doubt valuable. Some, not so much.

Here is the best part. A truckmount made by an international manufacturer with local distributors for installation and service starts out under $20,000 in the US. – the TITAN 325. The TITAN 325 platform is the number one selling nationally sold entry level truckmount in the world. Before you buy that 2003 rustbolt of a machine from someone you do not know, at least check that out as a possibility. If you do buy it you may want to keep some WD-40, chicken wire, and duct tape handy.

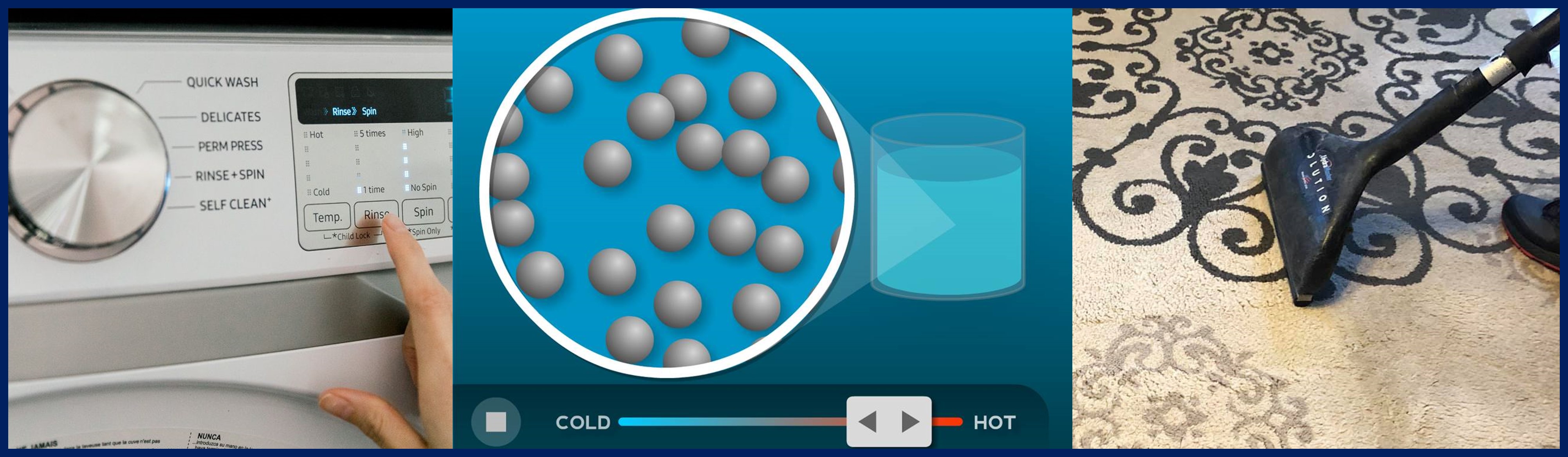

Cold Steve Austin is Stone Wrong. ICE T has never cleaned the carpet in a pizza restaurant. Drew Brees might want to check out the smelliest part of those football uniforms after they have been cleaned. You might have seen the television commercials by a leading washing machine detergent company highlighting the “alleged” money-saving and climate benefits of switching to cold-water cleaning when doing laundry. The use of all these celebrities: a famous wrestler, an actor, and a football player all lead to the conclusion that you are a better citizen and more planet friendly if you clean with cold water, plus you will save money.

Cold Steve Austin is Stone Wrong. ICE T has never cleaned the carpet in a pizza restaurant. Drew Brees might want to check out the smelliest part of those football uniforms after they have been cleaned. You might have seen the television commercials by a leading washing machine detergent company highlighting the “alleged” money-saving and climate benefits of switching to cold-water cleaning when doing laundry. The use of all these celebrities: a famous wrestler, an actor, and a football player all lead to the conclusion that you are a better citizen and more planet friendly if you clean with cold water, plus you will save money.